Product Development

Application Development

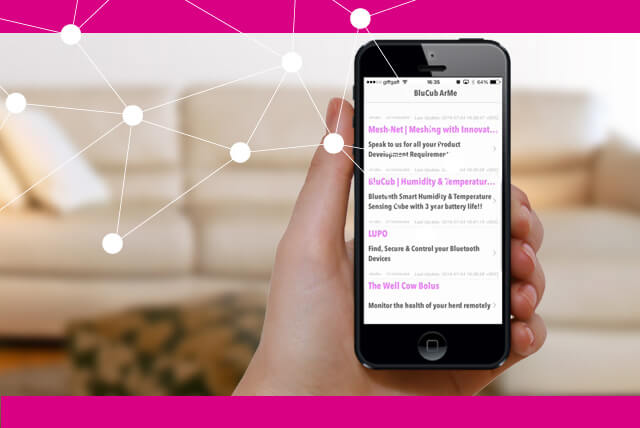

Mobile Application Development

Manufacturing

Product Creation

Initial Development

Development

Tooling

Manufacturing

Case Study - Wireless M-Bus

Challenge

Our client wanted to develop a product range that was compliant with the Wireless M-Bus protocol on two frequencies, on a minimum number of boards, meeting a cost sensitive market. The products had to be battery powered with battery lives of 5 years on a AA battery. A very unique product that would allow interfacing to industry-standard controllers and send their data over Wireless M-bus was also a requirement.

Process

The program of work started by defining the initial product range as well as the future possibilities. This ensured the developers were designing for the future and not just for this project. At the same time, understanding of Wireless M-bus and its specific requirements was equally important as it defined how the products would function. Based on this information, a clear program of work, deliverable and milestones was agreed with the client and a team assembled to carry out this work.

The Solution

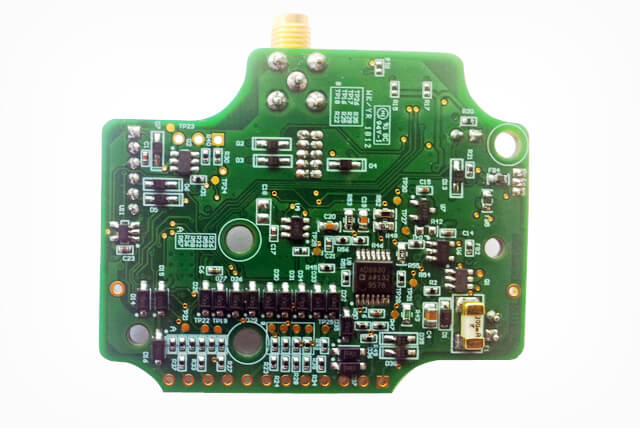

The team was set the challenge to develop one board for all the transmitters and one board for the receiver and repeater. With up to almost 30 variants of the product range, this was challenging in itself but important to the client to achieve a decent manufacturing cost on all the products, especially those that were not expected to be high volume. Design, testing, reliability, approvals were all part of the project, and different teams were placed within the project to deliver to their skill sets. Mesh-Net are proud to be working with the client who has more than quadrupled their wireless business as a result of this product range. Commitments are now in place to develop yet more ‘new technology’ products.

Business Services

Understanding

Development

Approval

Make Live

Case Study - Renewable Energy Monitoring

Challenge

Our client wanted to design a unique system that had a very specific purpose to suit their business needs. There were no other systems available in the market for them to use.

The Process

One of the most important parts of any development is to define an accurate specification. During the first part of the project we carried out a system study to fully understand the client’s needs, evaluate the equipment requirement, availability and define the acceptance criteria. On completion of this phase, the development team was suitably de-briefed, and project managed and delivered to agreed milestones. All through the development cycle, the client worked with us to ensure there were no late surprises.

The Solution

The solution involved a number of key components including multiple servers both for a staging and a live environment, M2M solution to collect data from remote devices, collection of energy and environmental data, and unique algorithms to generate the data required to provide reliable and up-to-date information on system performance. The client’s long-term vision was to read over 100k installations and, even though this is not expected to happen for sometime, the system performance had to be evaluated against this requirement. The project was delivered on time and the system was successfully made live.

Product Evolution

Understanding

Evaluation

Development

To Market

Case Study - Wireless Fleet Management System

Challenge

Our client, specialists in the logistics arena, had a requirement to determine if their goods-in-transit were tampered with. Larger fleet owners have invested in a Vehicle Management System that can provide part of the functionality but nothing was available for monitoring the trailers where there may no power and trailers can be shared between vehicles. Use of GSM or Satellite technology would not be practical due to power limitations and the additional running costs.

Process

We had to understand the process of goods-in-transit and the problems that some of the fleets experience to ensure what we developed was suitable for their needs. Some of the key criteria for this included battery powered devices, logging door open and close activity and providing the information to the gatehouse when the vehicle reached its destination.

Solution

The development required modification of Mesh-Net’s wireless products and a change in their functionality to suit the application. The program started by modifying one of the product’s hardware to provide additional memory and developing a unique strategy that would perform the logging and ‘listen out’ for messages from the gatehouse so the device knew when to download the data. The Gatehouse development was initially done on a Raspberry-Pi based platform and now plans are in place to develop a custom solution for this application. The system has been trialed on a number of sites and the feedback is very positive.

Project Feasibility

Can it work?

Technology Evaluation

Funding

Proof of Concept

Case Study – Intelligent Inhaler

Challenge

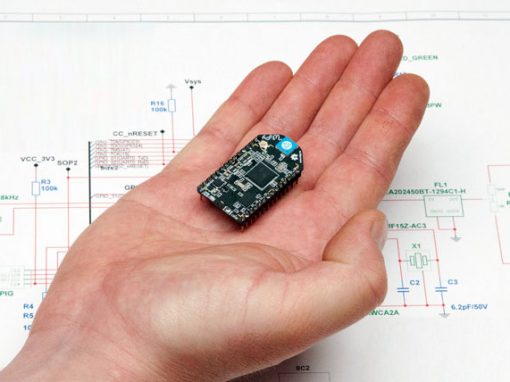

Many people have difficulties synchronising their breathing with the push of the inhaler that discharges the chemical into their throat. Our client wanted to investigate the possibility of having an automatic method to do this in a cost effective way.

Process

As this was more of a ‘proof-of-concept’ project, specifications and detailed documentation were not a requirement. Much of the functionality was defined in meetings and calls. The most important requirement was to have a flexible team in place that understood the final solution and was willing to change things ‘on the fly’ as needed.

Solution

Working with strong partners on this project was very important for us. The design of the enclosure and mechanical operation of the device could have been the success or failure of the project. With this in place and ideas on how the mechanical assembly would discharge the chemical, the focus was then to provide the electronics that would operate the mechanical parts. The design of the breath detection and algorithms to differentiate between ‘breathe-in’, ‘breathe-out’, normal airflow was key to avoid false triggering. The solution was successfully delivered to the client. The next stage will be to design a pre-production solution to meet the client’s production cost and run field trials. As this is a much larger project that may eventually be designed by much bigger companies, Mesh-Net is proud to have been part of something that could improve human lives.